Dongguan Lixian Instrument Scientific Co.,LTD

Dongguan Lixian Instrument Scientific Co., Ltd. is one of the

national leading manufacturers of advanced testing instruments,

which was found in 2000 and located in Dongguan, Guangdong province

of China.

Our manufacturer locate in Dongguan city,covers an area of 6000

square meters, take the lead in introducing the CNC processing

center and NC lathe and other advanced equipment in 2010. Carried

on several listed company lab, quality institutions,Tsinghua

University, Aeronautics University's project. We have more than

3000 buyers in domestic market,succeed in eastablishing the branch

companies and maintenance department in Dongguan, Shanghai,

Beijing, Jinjiang, Wuhan, Chongqing, Shenyang, Changsha, in the

same time, we have shoeroom and stock in Dongguan, Beijing,

Shanghai company.

Our products have achieved CE/ISO/ASTM/ROSH/UL certification,

exported to USA, Germany, South Korea, Greece, India, Singapore,

Brazil, Iraq, Saudi Arabia and other more than 60 countries.

Our machines are specially designed for many different material

research and quality control,such as metal, textiles, rubber,

adhesives, foodstuff and finished components and so on. A whole

series of tests including tension, shearing, compression, flex /

bending, tearing, peeling, friction, stiffness, vicat penetration

and torsion are available by our machine. Throught our work hard

and study, Dongguan Lixian Instrument Scientific Co., Ltd. has

maked progress in the software and hardware of our machine, which

accuracy has reached international advanced level and collection

resolution has reached to 1/500000. Dongguan Lixian Instrument

Scientific Co., Ltd. has the leading product development and

reliable quality management system,which introduced the CNC

processing center and CNC lathe and other advanced equipment in

2010, successfullly obtained the CMC measurement certificate and

passed ISO 9001 system authentication.

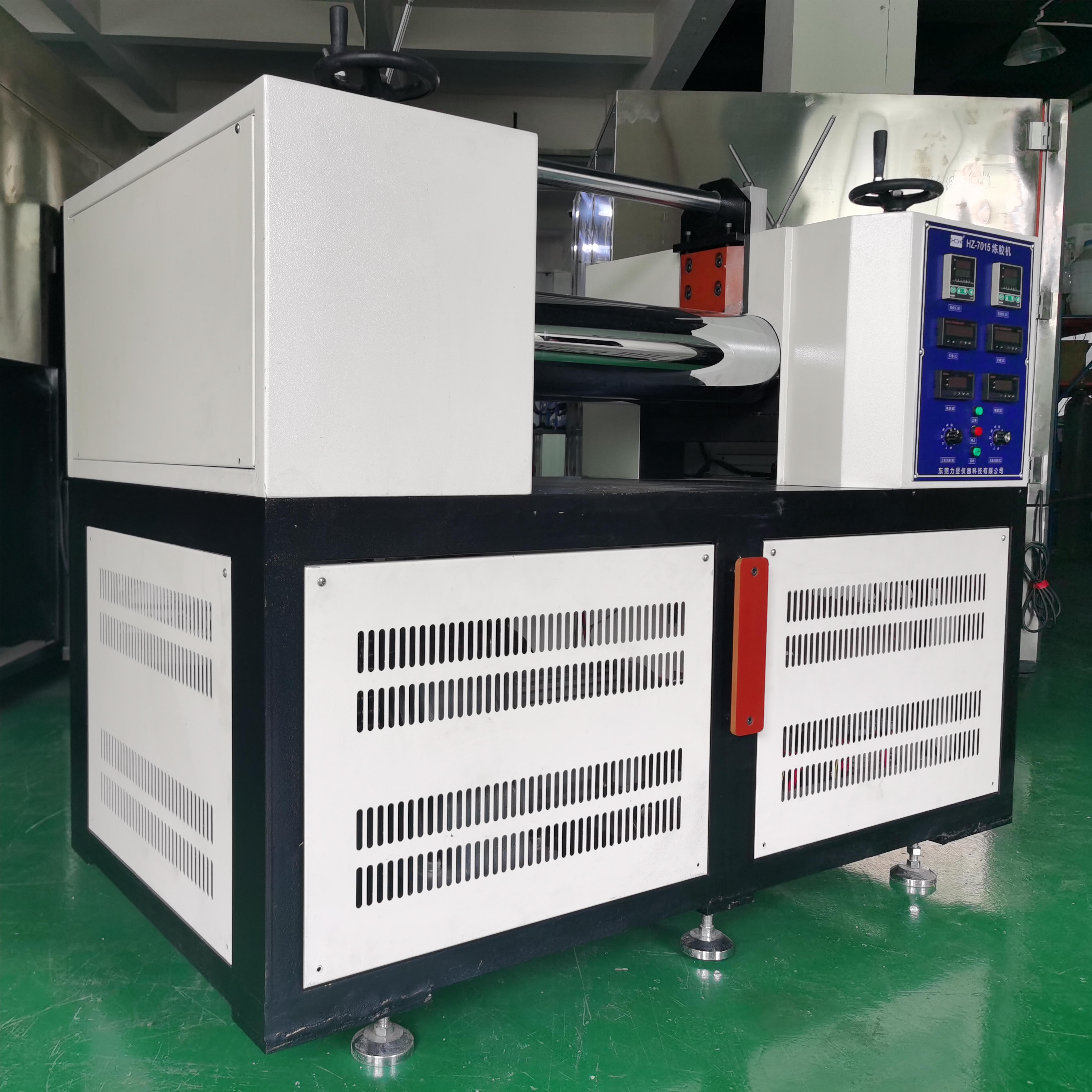

The main products of Dongguan Lixian Instrument Scientific Co.,

Ltd. are material testing machines, salt spray testing machines,

shoe testing machines, leather testing machines, packaging testing

machines, mobile phone and computer testing machines, textile

testing machines, rubber testing machines, stroller testing

machines, and sports equipment testing machines. Our products are

widely used in rubber & plastic, automobile production, medical

equipment aerospace, colleges and universities, foodstuff, building

materials, packing and other manufacturing industries.